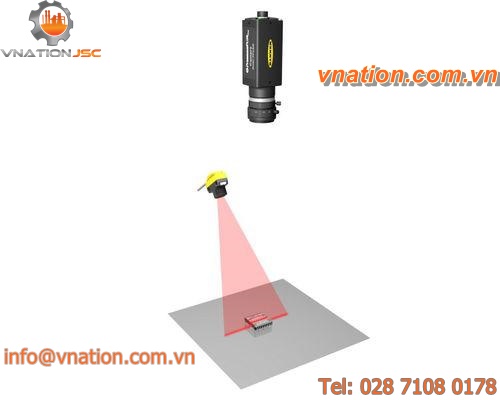

visual inspection machine

visual inspection machine

OSI40

Vnation JSC

-

Technology:

visual

Filled and closed syringe inspection is a major part of processing syringes that comes ready to use. These devices come with both visual and leak inspection mechanisms. Closed, filled syringes are automatically supplied one by one from the upstream machinery. As they progress through the machine, the syringes are rotated in front of a light source and magnified so that they may be inspected.

The faulty containers can be sorted out. The syringes that are correctly filled progress to the next machine. In the leak inspection mechanism, these devices would either be inserted manually or be provided by an upstream machine. High voltage inspections of both syringe barrels and, where applicable, the needle and glass connections are facilitated. Faulty products are removed. Those that pass inspection proceed onward.