optical inspection system / visual / automated / fast

optical inspection system / visual / automated / fast

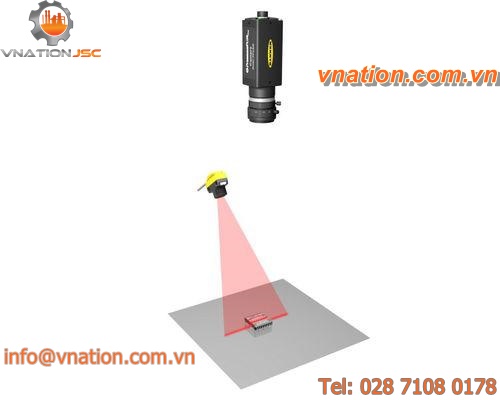

ICOS T830

Vnation JSC

-

Technology:

optical

-

Type:

visual, automated

-

Other characteristics:

fast

The ICOS? T830 provides high-performance, fully automated optical inspection of packaged integrated circuit (IC) components. It leverages high sensitivity with 2D and 3D measurements to determine final package quality for a wide range of device types and sizes. The ICOS T830 offers parallel operation of four independent inspection stations and a component sorting station, achieving high throughput, cost-effective component inspection.

Four independent inspection stations

Top Inspection

3D Inspection

5 Side Inspection

xCrack+ Inspection

xPVI?, extreme package visual inspection, enables high sensitivity detection of top and bottom component surface defect such as voids, scratches, pits, chips and exposed wires

xCrack+ provides accurate detection of die micro-crack defects that can cause thinner components to fail

5 Side inspection allows high-speed detection of EM shielding defects, voids, chips, cracks and other defects on the bottom and four sides of QFN and BGA packages

High-speed 3D ball, lead and capacitor metrology, package Z-height measurement and component side inspection ensures package quality

Supports all IC package types:

Leads: Thin Quad Flat Package (TQFP), Quad Flat Package (QFP)

Balls: BGA, Chip Scale Package (CSP), Wafer-Level Package (WLP)

Pads: QFN, Bump Chip Carrier (BCC)

Lands: Land Grid Array (LGA)

Package-on-Package (PoP): Interconnect

Fully automated tray pitch changeover

Pocket integrity check scans the trays to ensure there are no empty pockets or double units in the tray