monitoring vision system

monitoring vision system

CVS 20

Vnation JSC

-

Options:

monitoring

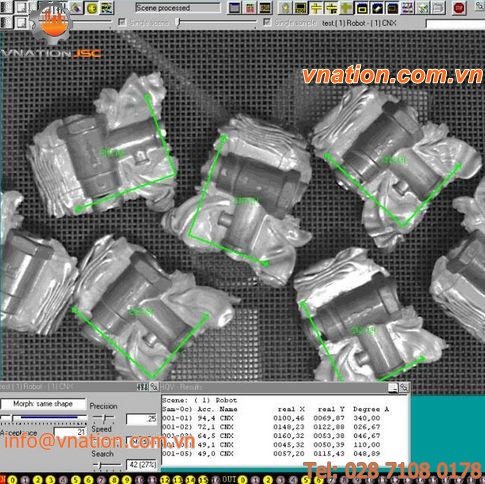

Dirty belts, wet parts, irregular boundaries, presence of machining residuals, bad illumination, difficult set-up, interlocking problems: today all these issues are no more a problem and it is possible to ride over them with our solutions based on the state-of-the-art technology.

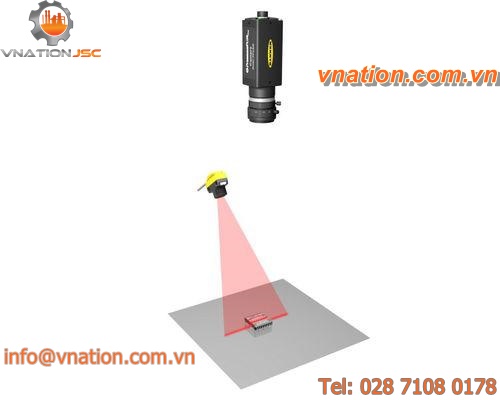

The use of advanced artificial vision technologies, both 2D and 3D, allows to correctly identificate and pick-up the parts even in unfavourable conditions, like a dirty belt or a conveyor similar to the part to be processed.

We are able to provide any kind of solution, from the small artificial vision system to the big full-automatic line, by using sensors and cameras for measuring, analyzing and, where necessary, certifying the production.

It is also possible to verify the correct assembly of the internal parts of a product, detecting those ones missing or placed in a wrong position, and make measurements (within the limits of the object?s detection).

Our After-Sale Service will assure the reliability of the system over the time, quickly responding to help, give suggestions and solve the problems.