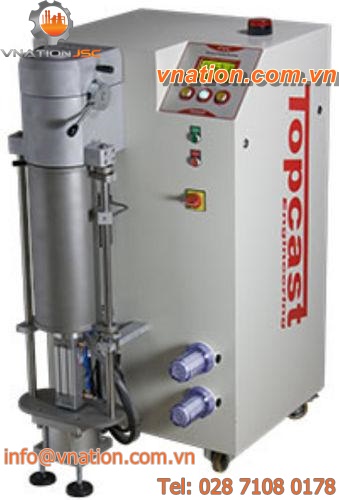

knife mill / for powders / plastics / horizontal

knife mill / for powders / plastics / horizontal

PS-K/PS-H Series

Vnation JSC

-

Technology:

knife

-

Material:

for powders, plastics

-

Orientation:

horizontal

-

Output:

Min.: 100 kg/h (220.46 lb/h)

Max.: 300 kg/h (661.39 lb/h)

Cutting / Knife Mills / UltraGranulator

Application:

For the size reduction of plastics, PALLMANN offers a variety of different knife mills. During the rotational moulding process hardly any rejects are produced. Mostly these parts are precut into smaller pieces and then granulated in a knife mill. For this purpose, PALLMANN has developed specific knife mills with throughput rates of 100 - 300 kg/h. For direct size reduction of larger rejects, we offer special knife mills with higher capacities and larger infeed openings. The granules so produced can be directly reintroduced into the pulverizer.

Method of operation:

The material is fed into the knife mill by means of a suitable feeding system. Size reduction is performed between the rotor knives and the stator knives built into the housing. The end fineness of the material is determined by the hole size of the screen installed. A hinged housing allows easy access to the grinding chamber. Screens and knives are thereby easy to clean and exchange.

Series:

Knife mills, series PS-K and PS-H are normally used for this application.