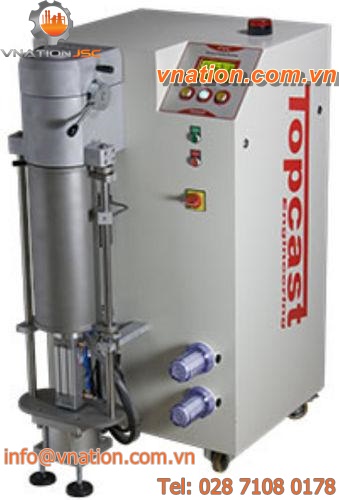

disc mill / for powders / plastics / for wood

disc mill / for powders / plastics / for wood

PALLTRUDER®

Vnation JSC

-

Technology:

disc

-

Material:

for powders, plastics, for wood

-

Orientation:

vertical

-

Output:

Min.: 200 kg/h (440.92 lb/h)

Max.: 2000 kg/h (4409.25 lb/h)

Palltruding / Palltrusion / PALLTRUDER?

Application:

With the PALLTRUDER?, mixtures of inorganic or organic materials can be processed into flowable granules (Wood-Plastic-Composite). Feed material can be in the form of powder, flake, film, fiber or foam.

Compounds produced with the PALLTRUDER? are very well suited for the production of high quality injection moulded or extruded parts such as pipes, profiles and sheets as well as for the production of board by means of double belt press technology.

Method of operation:

Natural material fibers - especially wood flour, plastic material in form of flake, chip, fiber or powder as well as lubricants and other additives - are fed into the PALLTRUDER? from different storage silos via a continuous turbo mixing screw. Frictional heat and high pressure, produced by a screw with a special pressure disc at its end, work the plastic into the natural fiber. Planetary knives cut the material coming out of the die into flowable granules at the outer circumference of the die.

Technical data of the PALLTRUDER? series:

Drive:

75 - 500 kW

Cool water consumption: 300 - 1.400 l/h

Throughput rate: 200 - 2.000 kg/h