foundry vibrating table

foundry vibrating table

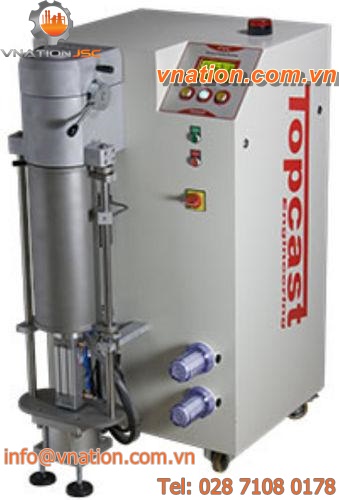

KM series

Vnation JSC

-

Applications:

foundry

COMPACTION TABLE

As one of the key components in foundry operations, compaction tables can ensure the efficiency and consistency in molding process and improve product quality by eliminating mold defects. Two main sections namely conveying and vibrating operate efficiently, producing perfect compaction of molds within flasks and core boxes. Depending on the size of the mold, the conveyor consists of rollers supported by either pneumatic or hydraulic lifters. Regardless of mold weight, high frequency vibratory motors can guarantee maximum mold compaction. Such qualities make ST series top choice as they ensure maximum dimensional accuracy in molding.