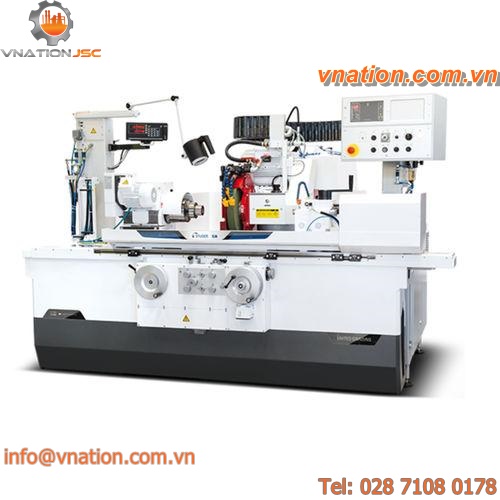

vertical honing machine / CNC

vertical honing machine / CNC

SV-25

Vnation JSC

-

Spindle orientation:

vertical

-

Control type:

CNC

-

Inner diameter:

Min.: 19 mm

Max.: 200 mm

The next generation of the successful SV-20 Series, introduced in 2013, is the competitively priced SV-25. With a proven ball-screw servo stroking system combined with a new PC control, the SV-25 produces precise bore geometries on compressor blocks, oil field components, multibore gas/diesel engine blocks and other similar applications.

Ideal for job shops, repair facilities, and performance and production engine shops, the SV-25 is available with a variable-speed 4.1 kW (5.5 hp) spindle motor, powerful enough to drive two-stage, metal-bond, diamond abrasives for short cycle times with high accuracy and minimal labor.

The SV-25 fills the void between the SV-15 and SV-2400 series in both price and features. The result is an affordable workhorse for a variety of applications with a proven track record.

FEATURES & BENEFITS

Full bore profile display projects a real-time display allowing you to dwell in the exact position where bore is visually smaller.

Reliable and precise servo ball-screw stroking mechanism improves geometry.

Built to handle large blocks including diesel engine blocks.

Standard tool protection feature automatically checks for obstructions prior to starting the cycle.

Windows? PC controlled with large 300 mm (15 inch) color touch screen.

Lifetime application service with every machine purchase.