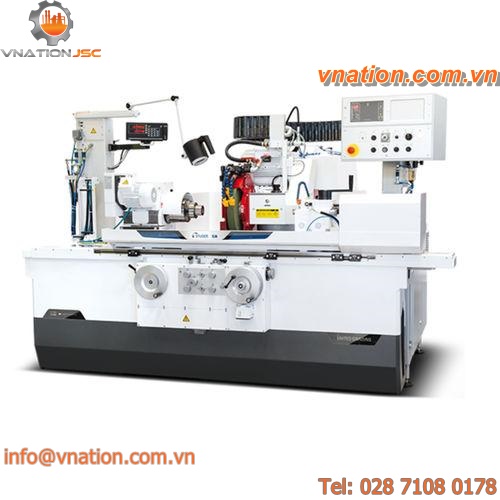

internal cylindrical grinding machine / CNC / radius grinding

internal cylindrical grinding machine / CNC / radius grinding

S121 Radius

Vnation JSC

-

Type:

internal cylindrical

-

Control type:

CNC

-

Associated function:

radius grinding

The S121 radius internal cylindrical grinding machine has an exceptional price/performance ratio and is the ideal machine for internal, face and external grinding of chuck components. It has a host of sophisticated technical features such as the revolutionary StuderGuide ? guideway system, high-precision axis drives with linear motors, a fully automatic B-axis with direct drive, etc.

The S121 is especially suitable for grinding complex workpieces from very hard materials such as tungsten carbide, ceramic and sapphire as well as for general grinding tasks. Optimal stability and rigidity enable diameters, cones and transitional radii (ground using the pendulum method through interpolation of the B and X/Z axes) to be ground to a polished surface quality. The machines are ideal for the manufacture of dies, especially in the packaging industry, where tungsten carbide and ceramic are primarily processed. Hydraulic components such as axial pump pistons, guide plates and housings made of hardened steel, cast iron and copper can also be produced. Other fields are the production of complex workpieces with several tapers greater than 20 to 90 deg in a single clamping, where the main applications are in the watch and medical industries with extra-hard materials such as industrial ceramic, sapphire and tungsten carbide, as well as the manufacture of human implants for shoulders, knees and hips from ceramic and titanium.