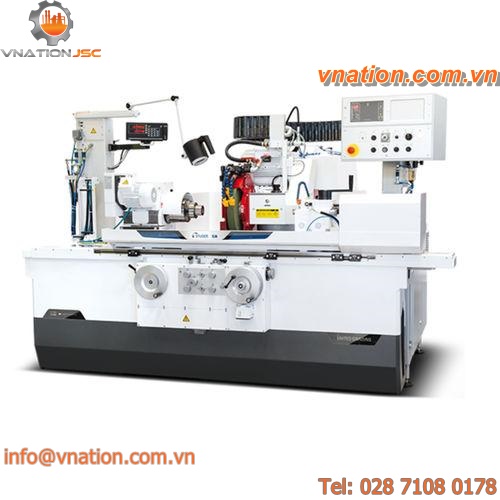

external cylindrical grinding machine / CNC / 2-axis / for gearing

external cylindrical grinding machine / CNC / 2-axis / for gearing

MKS1332, MKS1632

Vnation JSC

-

Type:

external cylindrical

-

Control type:

CNC

-

Number of axes:

2-axis

-

Applications:

for gearing, for crankshafts

-

Spindle speed:

Min.: 30 rpm (188.5 rad.min-1)

Max.: 300 rpm (1884.96 rad.min-1)

-

Distance between centers:

Min.: 750 mm

Max.: 1500 mm

Features of the machine tool performance and structure

As middle and high grade CNC machine tools, MKS1332 and MKS1632 CNC (endface) external cylindrical grinding machines are independently developed on the basis of applying new technologies and rich experience of designing and manufacturing CNC grinding machines. Characterized by the universalization, high-degree modularization, high rigidity, high efficiency, high adaptability, high precision, easy to operate and reliable performance,these machines are suitable for the mass productive processing of automobile engine crankshaft, camshaft, differential housing, flange plate, and parts of transmission system, such as transmission shaft, half shaft, gear (wheel) shaft, etc., in addition, they also can be applied in the small-scale high precision productions in workshops of military industries, aviation industry, aerospace industry and common precision machining.

With the rational layout and integral protective cover, the machine tool is convenient for maintenance and in conformity with human engineering requirements.

With a sleeve type hydrostatic/hydrodynamic mainshaftingadopted for the grinding wheel spindle, the machine tool features on the high rotary precision and good rigidity. The linear speed of the grinding wheel can reach 60m/s (for specially ordered) and that of CBN grinding wheel is 80m/s (for specially ordered).

With two-axis linkage feeding, the machine tool is equipped with worktable (Z axis) and a wheel head (X axis) drivenbyAC servomotor and ball screws, with minimum setting unit of 0.1?m and maximum fast feed speed of 20m/min.