automatic feed chamfering and deburring machine / straight edges / weld preparation / angular adjustment

automatic feed chamfering and deburring machine / straight edges / weld preparation / angular adjustment

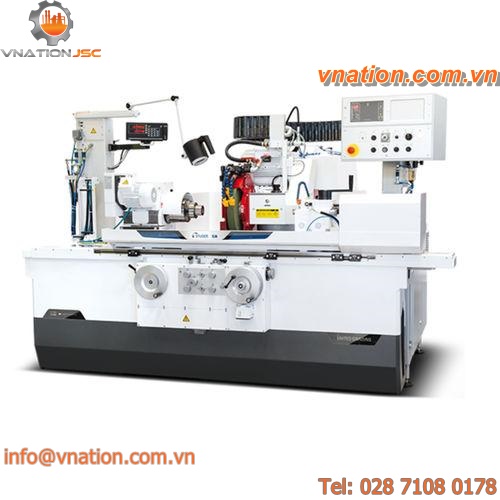

WKF 170

Vnation JSC

-

Operation:

automatic feed

-

Applications:

straight edges, weld preparation

-

Other characteristics:

angular adjustment

The perfect machine for chamfering small to mid-size work pieces and bar material. Thanks to its angle adjustment from 15? 60?, it is mainly used for weld seam preparation.

Professional advantages:

- Simple and fast angular adjustment

- Consistent high surface quality

- Automatic feed facilitates chamfering

- Sharp-edges chamfering is possible, i.e. a 5 mm ? 45? chamfer can be applied to a 5 mm thick work piece

Application:

- Minimum work piece thickness 1 mm

- Can be used for steel, max. 1,000 N/mm?, aluminum, brass, copper, plastic, from soft plastic to acrylic glass, wood and much more

- Deburring work pieces up to weld seam preparation

Options:

- Mobile undercarriage with big rubber rollers and integrated swarf drawer

- Lateral stop for processing the front side

- Longitudinal stop for safe guidance of mass-produced parts

- Automatic feed for single-part and series production and processing bar materials

- Roller conveyors for extending the guide rails

Features:

- Angular adjustment from 15 ? 60 ? (set-out every 5? possible)

- Chamfer adjustment by micrometer button

- Speed control for processing different materials

- Uncomplicated tool change

- Hardened and polished guide rails

- Soft cutting pressure

Delivery contents:

- Torx key T 25

- Plane cutter head with cutting inserts

- Operating instructions

Further accessories can be found in our Accessory Catalogue.