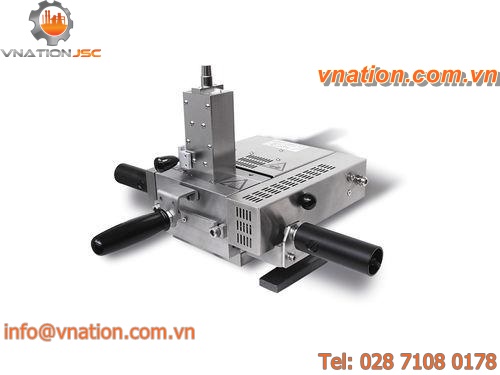

measuring kneader / batch / vertical / laboratory

measuring kneader / batch / vertical / laboratory

MIR-S100C-PE

Vnation JSC

-

Associated function:

measuring

-

Batch/continuous:

batch

-

Orientation:

vertical

-

Other characteristics:

laboratory

Measuring mixers: for rheological tests and production simulation on a laboratory scale

What does this instrument do?

Brabender measuring mixers serve for the non-continuous production of homogeneous polymer, elastomer, ceramic or other mixtures. If connected to a drive unit (torque

rheometer), the torque and the stock temperature can be measured and recorded during the mixing process.

Why is this important?

On a laboratory scale, all processes relevant for the production and processing of polymers and other plastic and plastifiable materials, such as compounding, mixing, masticating, etc. can be simulated. As an example, the fusion time of PVC and other materials can be determined precisely and related to the estimated residence time of the material in an extruder.

How does this instrument work?

The measuring principle is based on the measurement of the torque which mirrors the resistance the material opposes to the rotating blades during the mixing process. The torque moves a dynamometer out of its zero position. This path can be measured and visualized as a function of time. The resulting diagram illustrates the relationship between torque (viscosity) and temperature over the measuring time and also shows structural changes of the material.

What are the benefits?

- Easy handling and cleaning through bipartite (with liquid heating/cooling) or tripartite

(with electric heating) mixer bowl, quickly detachable and partially interchangeable mixer blades

- Flexibility: broad range of mixer blades geometries optimized for particular measuring tasks

- Accuracy: Precise and constant heating / cooling of the mixers