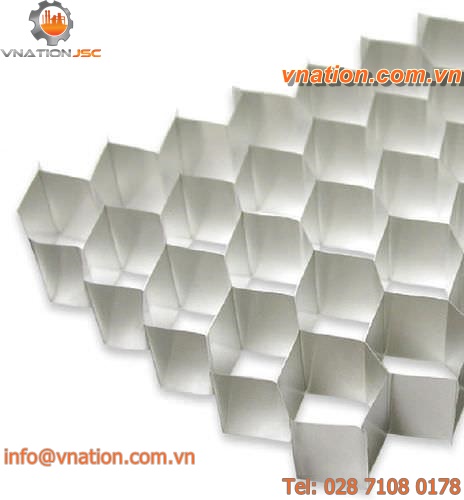

core material / impact-resistant

core material / impact-resistant

GURIT® CORECELL™ A

Vnation JSC

-

Options:

impact-resistant, foam for composites

GURIT? CORECELL? A - STRUCTURAL CORE MATERIAL

MAIN PRODUCT FEATURES

? Ultra tough foam suited for slamming applications

? Exceptional impact tolerance

? Suitable for dynamically-loaded structures

? Superior styrene and temperature resistance to linear PVC foam

? Highly thermoformable

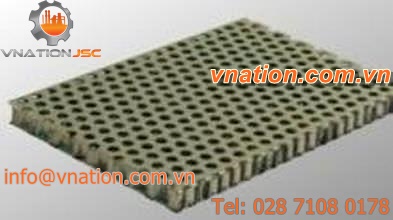

? Ideal for resin infusion

INTRODUCTION

Gurit? Corecell? A is the original Corecell material, developed because of frustrations with inadequate PVC core technology in marine sandwich structures. Gurit? Corecell? A is well known for its incredible toughness and resistance to cracking, which comes from its high ductility. Gurit? Corecell? A can elongate up to 65% in shear before failure, making core shear failure in a laminate almost impossible.

Tests and experience show that Gurit? Corecell? A is the most reliable core material for dynamic loading situations where PVC and balsa may fail due to poor shear elongation properties.

For the manufacturer, Gurit? Corecell? A offers the benefit of high resistance to styrene and other chemicals and better thermal stability than linear-PVC foam. Gurit? Corecell? A is also highly thermoformable, which is useful in many applications where cutting the core material is undesirable.

Gurit? Corecell? A is available in every resin infusion format and is compatible with polyester, vinylester and epoxy resin systems. The low resin absorption characteristics of Gurit? Corecell? and its unique knife-cut formats deliver higher performing infusions, low resin cost and low weight. This combination makes Gurit? Corecell? a key part of a reliable package.