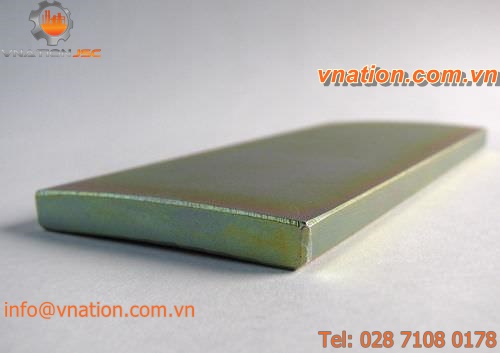

segment shaped magnet / NdFeB

segment shaped magnet / NdFeB

ExxxNEO series

Vnation JSC

-

Configuration:

segment shaped

-

Material:

NdFeB

NdFeB magnets achieve the highest energy density today. The most used production process is the powder metallurgical procedure.

The saturation magnetic polarization of the ferromagnetic main phase Nd?Fe14B constitutes 1.62 T. From this follows a maximum achievable energy density of 64 MGOe.

At laboratory conditions a maximum energy density of approx. 59 MGOe was achieved. With regard to mass production it is possible to produce permanent magnets with energy densities of ca. 59 MGOe for applications at up to 70?C. In spite of these excellent material properties sintered NdFeB magnets are characterized by some weaknesses compared to SmCo magnets.

Comparatively low Curie temperature of 312?C, which results in higher temperature coefficients of the remanence and coercivity and which limits the possible operating temperatures

High corrosion sensitivity