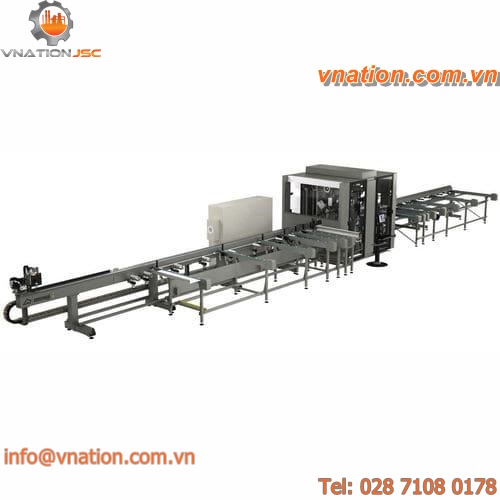

CNC machining center / 3-axis / universal / double-column

CNC machining center / 3-axis / universal / double-column

BTMC-1302

Vnation JSC

-

Control type:

CNC

-

Number of axes:

3-axis

-

Spindle orientation:

universal

-

Structure:

double-column

-

X travel:

2200 mm

-

Y travel:

1300 mm

-

Z travel:

800 mm

-

Rotational speed:

6000 rpm (37699.11 rad.min-1)

-

Power:

Min.: 15 kW (20.12 hp)

Max.: 18.5 kW (24.81 hp)

1. CNC double column design for large parts machining

2. Time aged casting

3. X axis hardway or Linear way, Z axis Hardway

4. Y axis Heavy duty loading linear way

5.Controller: FANUC/MITSUBISHI

Special model:

Gear head gantry type machining center

-Equiped with ZF gear reducer box(German) or gear type spindle-case (Taiwan),which can achieve high strength cutting

Multiple functional gantry machining center

--Can be equipped with direct - connection type milling head, high speed spindle,which can achieve high rotation speed cutting.

--Can be equipped with Taiwan90' angel milling head, which can meet simple horizontal processing requirement.

--Can be equipped with Taiwan universal milling head,which can meet achieve simple mutiple angel processing needs.

--Can be equipped with auto pentahedral milling head,which can achieve multi-surface high precision processing.

Product features:

*Serial 13 and serial 15 have either hard way X axis and linear way Y axis or X&Y axis are both linear way. For the other serials, X&Y axis are all heavy-load roller linear way. Zaxis for all models is rectangularslide way.

*High quality resin sand casted,gantry type frame structure, Z axis employs laminated slide way system,which suits high rigidity and high precision parts processing.

*Equipped with Europe imported gear box, rack and coupling(French brand gear driving box, Swiss brand rack and German bran coupling), Japanese /German brand linear guide wayand spindle bearing adopt. Lead screw, block nut, pulley, spindle, hydraulic balance systemare from Taiwan the top brand's top quality accessories,which ensure high precision,high quality and high stability.