fluidized bed granulator / wet / for pharmaceutical applications

fluidized bed granulator / wet / for pharmaceutical applications

BCG ®

Vnation JSC

-

Type:

wet, fluidized bed

-

Applications:

for pharmaceutical applications

Granulation

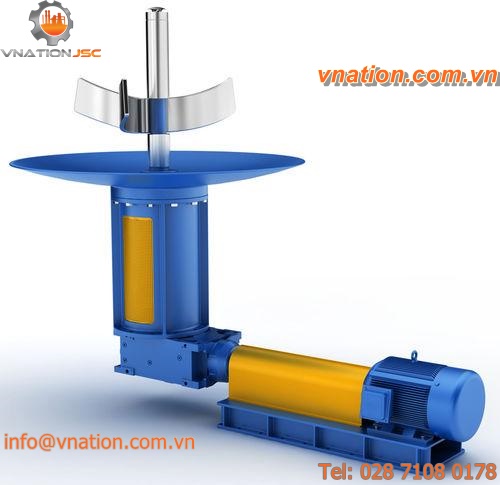

Bohle Conti Granulator BCG ?

Continuous processes are strongly increasing in the pharmaceutical industry. At the Interpack 2011 in D?sseldorf, L.B. Bohle will introduce the first Bohle Conti Granulator BCG ? - a twin-screw extruder with a downstream dryer.

The core of the system is a newly designed GMP-compliant twin-screw extruder, supplied by a continuous mass-controlled powder dosing unit and a continuous liquid dosing unit. The finished granule falls directly into the continuous rotating vacuum contact dryer, without the usual transport problems. The dryer operates with an innovative blending and dispersing unit to reliably prevent the wet granule caking to any surface. The final granule site is then adjusted using the well known Bohle Turbo Sieve BTS.

The benefits of the Bohle Conti Granulator BCG ?:

the monoblock design features no dead spaces or connections which makes installation and cleaning easy

the torque measurement is particulary noteworthy, allowing outstanding control of the process

the new continuous rotating vacuum dryer of the Bohle Conti Granulator BCG ? system features significant advantages versus other systems